Many of us have heard that water and oil don’t mix. But tricking nature has brought out the best ingredient for cosmetics and other beauty products.

Emulsifying wax is a versatile ingredient used in the cosmetic industry that allows water and oil to mix into a delicate creamy product. These form the basis of all sorts of skincare products, hair care products, and other cosmetics.

What Is Emulsifying Wax?

Emulsifying wax is a cosmetic ingredient that is used to bind oil and water together to form a smooth lotion, cream, and emulsion. Emulsifying wax is created when a vegetable wax is treated with a detergent to cause it to make oil and water bind together into a smooth emulsion. They are made from plant-based oils, hence, they are safe to use.

Emulsifying wax finds use mainly in creams and lotions as an ingredient that protects the moisture-retaining capacity of the product. They maintain a skin-friendly consistency and remove the original greasiness of the ingredients combined in them.

Most importantly, these emulsifying waxes hold all the ingredients including the oils and water, together, throughout the product life.

Note – Always check the INCI (the ingredients list for the ingredient) of emulsifying wax before purchasing it because some suppliers change the name of the products.

Types Of Emulsifying Wax

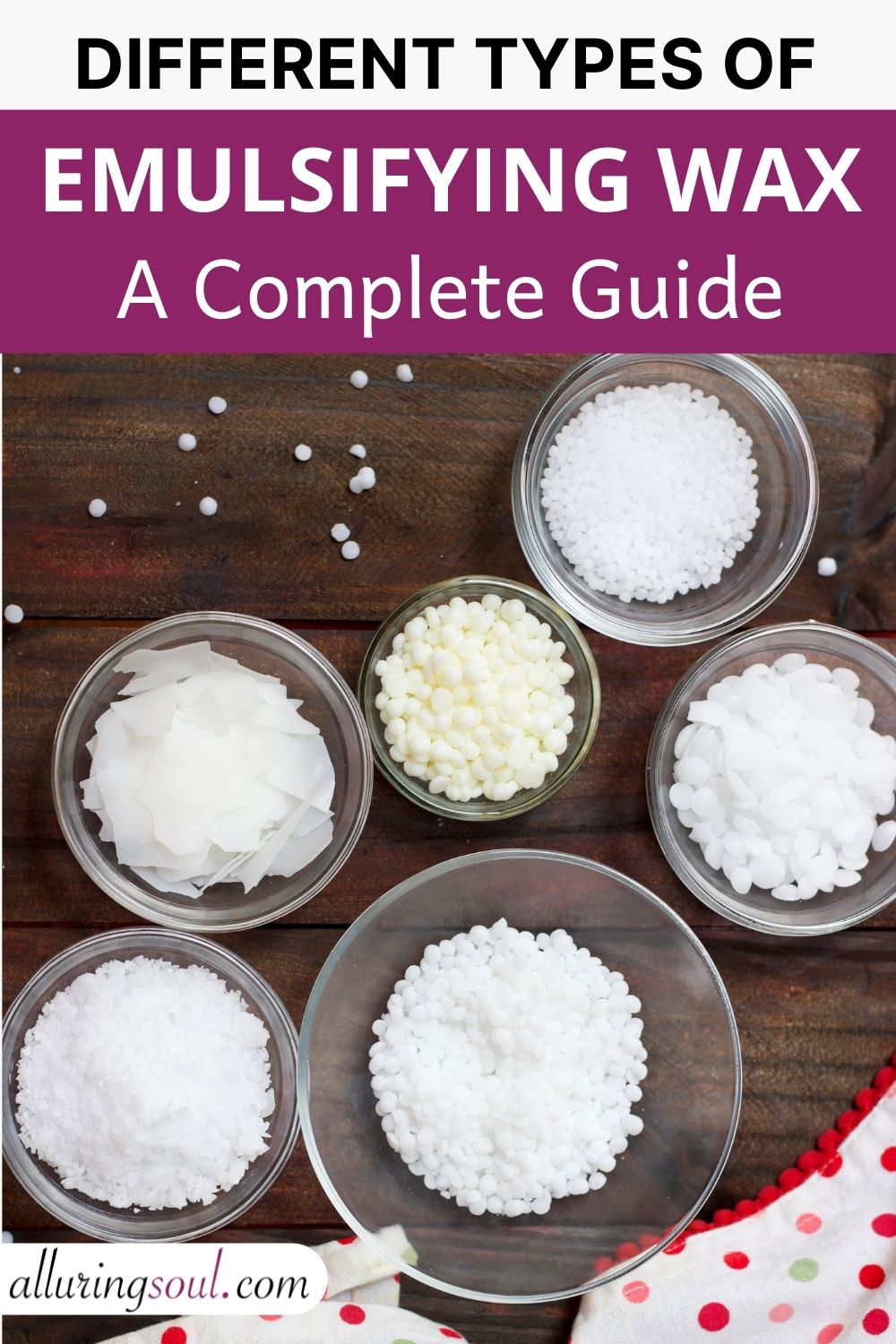

There are various types of emulsifying wax available in the market. Though this is not a complete and exhaustive list of emulsifying wax, there are basic types of emulsifying wax that can be used by beginners, available in most parts of the world, and are easy to work with. They are –

1. Emulsifying Wax NF

Emulsifying Wax NF is a USP-certified emulsifying Wax, known by many names around the world. And they are widely used to make emulsions of any desired consistency.

INCI: Cetearyl Alcohol (and) Polysorbate 60 (INCI is the ingredient list used to make that product)

Appearance: Emulsifying waxes appear as white, waxy lumps that are smooth to touch. It comes in beads, pellets, and flaky form.

Solubility: It is soluble in oil and is added to the oil phase of any formulation.

Usage Rate: 2–25% of the final weight of the formulation, though 25% would be inappropriate to use in almost everything.

What does “NF” means in emulsifying wax NF?

The initials ‘NF’, which stands for ‘National Formulary’, suggests that the particular emulsifying wax comes under certain standards dictated by the United States Pharmacopeia.

Emulsifying Wax NF is recognized as an individual ingredient because it passed the standards of USP and earned the initials. Otherwise, it would be considered a combination of other components that are required to be listed on the product as well.

How Emulsifying Wax NF is made?

Emulsifying wax NF is made of Cetearyl Alcohol and glyceryl stearate which are fatty acids and Polysorbate 60, an emulsifier. These fatty acids are derived from plants, making them vegan ingredients. Unlike the name, they are not related to beeswax or other waxes.

Is Emulsifying Wax NF Natural?

There is a lot of controversy regarding the safety of this ingredient when considering the components used to create the emulsifying wax NF.

So, is it natural? Yes, based on the fact that it is derived from plants, it has a natural origin. But It is not fully natural. Since the creation of this ingredient requires first processing its plant-based components before using them in other cosmetics, it is hard to accept their safety without prior research.

| EMULSIFYING WAX NF | |

| What is it? | Emulsifying wax nf is a cosmetic ingredient that is used to bind oil and water together to form a smooth lotion, cream, and emulsion. |

| How it is made? | It is created when a vegetable wax is treated with a detergent to cause it to make oil and water bind together into a smooth emulsion. |

| INCI | Cetearyl Alcohol (and) Polysorbate 60 (INCI is the ingredient list used to make that product) |

| Appearance | white, waxy lumps that are smooth to touch. It comes in beads, pellets, and flaky form. |

| Solubility | It is soluble in oil and is added to the oil phase of any formulation. |

| Usage Rate | 2–25% of the final weight of the formulation, though 25% would be inappropriate to use in almost everything. |

| Is it safe to use? | Yes. |

| Does emulsifying wax nf clog pores? | No. Emulsifying wax nf does not clog pores. It has a comedogenic rating of 1. |

2. BTMS Conditioning Emulsifier

Behentrimonium Methosulfate or for short BTMS is simply a type of emulsifying wax. It is used in making mainly hair care products like shampoos and conditioners. They provide a natural shine to your hair since they have added conditioning properties.

There are two types of BTMS –

- BTMS 25 (INCI: Behentrimonium Methosulfate (and) Cetearyl Alcohol)

- BTMS 50 (INCI: Behentrimonium Methosulfate (and) Cetyl Alcohol (and) Butylene Glycol

BTMS-25 contains 25% Behentrimonium Methosulfate, the active conditioning ingredient in BTMS. BTMS-50 contains 50% Behentrimonium Methosulfate, the active conditioning ingredient in BTMS. BTMS-25 doesn’t emulsify as well as BTMS-50, also, BTMS 50 has more conditioning effect than BTMS 25. So, BTMS-50 is best to use in your conditioners if you have dry hair. If you have greasy hair you might prefer BTMS-25.

BTMS 50 works well with other emulsifiers if you ever need to add additional properties to your hair conditioners or creams. BTMS 50 can also be used alone and they are easy to emulsify.

Appearance: BTMS 25 And BTMS 50 are white, yellowish, & waxy and do not absorb water quickly. They come in beads or pellets form.

Solubility: BTMS 25 And BTMS 50 are found to be soluble in oil and not in water. They are added to the oil phase in any formulations.

Usage rate: 1–15% of the final weight of your formulation.

How BTMS 50 Is Made?

BTMS 50 is synthetically derived from modified Rapeseed oil. It contains Cetyl alcohol and butylene alcohol which is derived from petroleum.

Is BTMS 50 natural?

BTMS 50 is not all natural but a synthetic derivative of Rapeseed oil. It contains butylene alcohol which is popularly known to enhance texture and boost penetration. It is known for making up skincare ingredients, and you can consider it safe.

| BTMS (Behentrimonium Methosulfate) Emulsifier | |

| What is it? | BTMS or Behentrimonium Methosulfate is a cosmetic ingredient that is used to bind oil and water together to form a smooth lotion, cream, and emulsion. It is used in making mainly hair care products like shampoos and conditioners. They provide a natural shine to your hair since they have added conditioning properties. |

| Types Of BTMS | 1. BTMS 25 (INCI: Behentrimonium Methosulfate (and) Cetearyl Alcohol) 2. BTMS 50 (INCI: Behentrimonium Methosulfate (and) Cetyl Alcohol (and) Butylene Glycol) |

| How BTMS is made? | It. is synthetically derived from modified Rapeseed oil. |

| Appearance | BTMS 25 And BTMS 50 are white, yellowish, & waxy and do not absorb water quickly. They come in beads or pellets form. |

| Solubility | BTMS 25 And BTMS 50 are found to be soluble in oil and not in water. They are added to the oil phase in any formulations. |

| Usage Rate | 1–15% of the final weight of your formulation. |

| Is it safe to use? | Yes. |

3. Olivem 1000

It is a non-ionic primary oil-in-water emulsifier and utilizes the chemistry of olive oil. In lotions and creams, it functions as an all-in-one emulsifier as well as it also thickens the product. It is used in skincare and haircare products. They are associated with maintaining liquid crystals on your skin, which is needed to prevent wrinkle formations. Its strong soaping effect makes it a great ingredient for hair conditioners. Also, it effectively hydrates the skin.

INCI: Cetearyl Olivate & Sorbitan Olivate.

Appearance: It appears as white, thin flakes, having a fine texture.

Solubility: Olivem 1000 is soluble in oil at 75 degrees Celsius and forms an emulsion.

Usage rate: 2-10% of the final weight of the formulation.

How Olivem 1000 is made?

It is mostly obtained from Olive oil and mixed with an emulsion stabilizer plus sorbitol.

Most of the emulsifying agents contain Polyethylene Glycol, which is a component processed via ethoxylation. This process makes the product quite harmful for use. However, Olivem 1000 does not use this product in its making. Hence you can consider it as an ideal emulsifying wax, with no PEG compounds. Moreover, it is quite easy to blend with other ingredients that have a lower Ph (Aloe Vera).

Is Olivem 1000 natural?

Yes, it is an all-natural ingredient. Olivem 1000 is biodegradable, which makes it environmentally friendly.

| OLIVEM 1000 | |

| What is it? | It is a non-ionic primary oil-in-water emulsifier and utilizes the chemistry of olive oil. In lotions and creams, it functions as an all-in-one emulsifier as well as it also thickens the product. |

| How it is made? | It is mostly obtained from Olive oil and mixed with an emulsion stabilizer plus sorbitol. |

| INCI | Cetearyl Olivate & Sorbitan Olivate. |

| Appearance | It appears as white, thin flakes, having a fine texture. |

| Solubility | It is soluble in oil and is added to the oil phase of any formulation. |

| Usage Rate | 2-10% of the final weight of the formulation. |

| Is it natural? | Yes. |

4. Ritamulse SCG (Emulsimulse)

Ritamulse SCG (Emulsimulse) is yet another plant-derived and complete emulsifying wax having anionic lactylates that acts as factors that enhance the natural lactic acid and fatty acids present in our skin. Now, these two compounds are responsible for moisturizing our skin! They are excellent ingredients for lotions, hair creams, skincare creams, and other organic products.

Ritamulse SCG is known for creating foamy lotions that are quite satisfying to use. They have a great ‘soaping effect’ making them ideal for hair conditioners and body washes.

Ritamulse SCG is not versatile like emulsifying wax nf. It requires proper formulation to make a stable emulsion. It is Ph sensitive and not compatible with cationic ingredients. Ritamulse SCG only creates stable emulsion with an oil phase of up to 25%.

INCI: Glyceryl Stearate (and) sodium stearoyl Lactylate (and) Cetearyl alcohol.

Appearance: It has a fine texture and appears like thin white flakes that are lightweight.

Solubility: It is readily soluble in oil.

Usage rate: Up to 10% of the final weight of the formulation. Most products stick to a magnitude of 4% to 8% of use.

How Ritamulse SCG is made?

It is made from acyl lactylates and is completely plant-based emulsifiers. They are gluten-free and ECO-Cert approved.

Is Ritamulse SCG natural?

It is plant-derived emulsifying wax. The manufacturing process involves the use of natural ingredients, approved by ECO-Cert. So you would not have to worry about any sort of side effects.

Ritamulse SCG (Emulsimulse) Emulsifier | |

| What is it? | Ritamulse SCG (Emulsimulse) is yet another plant-derived and complete emulsifying wax having anionic lactylates that act as factors that enhance the natural lactic acid and fatty acids present in our skin. |

| How it is made? | It is made from acyl lactylates and is completely plant-based emulsifiers. They are gluten-free and ECO-Cert approved. |

| INCI | Glyceryl Stearate (and) sodium stearoyl Lactylate (and) Cetearyl alcohol. |

| Appearance | It appears as white, thin flakes, having a fine texture. |

| Solubility | It is soluble in oil and is added to the oil phase of any formulation. |

| Usage Rate | up to 10% of the final weight of the formulation. |

| Is it natural? | Yes and ECO-Cert approved. |

5. Polawax

Polawax NF is a plant-derived and a complete emulsifying wax used to make an oil-in-water emulsion. It is thick emulsifying waxes that are nonionic and find use in hand creams, lotions, scrubs, moisturizers, and cleansers.

It is found in the market exclusively for high-quality lotions and creams. Since these have great stability and enhanced viscosity, you can count on them alone for your skin-care product. Moreover, they are gentle yet give adequate thickness to the combination.

INCI: Cetearyl Alcohol (and) PEG-150 Stearate (and) Polysorbate 60 (and) Steareth-20

Appearance: It appears as white waxy beads or pellets or pastilles.

Solubility: It is soluble in oil and is added to the oil phase of an emulsion.

Usage: Up to 25% of the final weight of the formulation can be used in products.

How Polawax is made?

Polawax is made from Polysorbate 60, PEG-20 Stearate, and Cetearyl Alcohol. These ingredients are completely plant-derived and give Polawax self-emulsifying properties.

Is Polawax natural?

In short, Polawax is not all-natural. It has had certain drawbacks considering the ingredient PEG-20 stearate is used sometimes in the manufacturing process. This component is known to be a product of ethoxylation.

However, various Polawax manufacturers have shifted to a substitute for this ingredient. All the ingredients are plant-based to a great extent.

POLAWAX | |

| What is it? | Polawax NF is a plant-derived and a complete emulsifying wax used to make an oil-in-water emulsion. It is thick emulsifying waxes that are nonionic and find use in hand creams, lotions, scrubs, moisturizers, and cleansers. |

| How it is made? | Polawax is made from Polysorbate 60, PEG-20 Stearate, and Cetearyl Alcohol. These ingredients are completely plant-derived and give Polawax self-emulsifying properties. |

| INCI | Cetearyl Alcohol (and) PEG-150 Stearate (and) Polysorbate 60 (and) Steareth-20 |

| Appearance | It appears as white waxy beads or pellets or pastilles. |

| Solubility | It is soluble in oil and is added to the oil phase of an emulsion. |

| Usage Rate | up to 25% of the final weight of the formulation. |

| Is it natural? | Not all-natural. |

Other types Of Emulsifying Wax

This is by no means a complete and exhaustive list of emulsifying wax.

- Glyceryl Stearate SE (INCI: Glyceryl Stearate SE)

- LotionPro 165 (INCI: Glyceryl Stearate (and) PEG-100 Stearate)

- Behentrimonium Chloride (INCI: Behentrimonium Chloride)

- Varisoft® EQ 65 (INCI: Distearoylethyl Dimonium Chloride, Cetearyl Alcohol

- MONTANOV 202 (INCI: Arachidyl alcohol, Behenyl alcohol, Arachidyl glucoside)

- Vegetal / Montanov 68 (INCI: Cetearyl Alcohol and Cetearyl Glucoside)

- Olivem 900 (INCI: Sorbitan Olivate)

Are All Emulsifying Waxes The Same?

Not all emulsifying waxes are the same.

1. There Are Two Types Of Emulsifying Waxes.

- Oil In Water (O/W) emulsifier. Many emulsifying waxes are oil-in-water emulsifiers. It means these types of emulsifiers help to emulsify a smaller amount of oils added in a larger amount of water. Examples – emulsifying wax nf. BTMS, Olivem 1000, Ritamulse SCG, Polawax, etc.

- Water In Oil (W/O) emulsifier. It means these types of emulsifiers help to emulsify a smaller amount of water added in a larger amount of oils.

If you want to use an oil-in-water emulsifier to add a small amount of water to a body butter or balms, it may not make a stable emulsion or formulation. For adding a small amount of water to a mostly oil-based product, you’d need a water-in-oil (W/O) emulsifier.

2. Different Emulsifying Waxes Create Emulsion With Different Texture and Consistency.

The consistency and texture provided by emulsifying waxes in creating emulsion is the main factor that strays them apart. If you substitute an emulsifying wax with another, the product may not have the same texture and consistency as the one in the original recipe. But you will be able to create a successful emulsion.

There are some emulsifying waxes that make thicker emulsions than others when used at the same concentration. Some emulsions will feel lighter and smoother than others while some give more of a cream-like consistency. Depending on the range of thickness and texture that you wish to acquire in your products, you may choose from the different types of emulsifying waxes.

Example – Glyceryl Stearate (and) PEG-100 Stearate emulsifying wax will not thicken your formulations but emulsifying waxes like Emulsifying wax NF, Olivem 1000 and Polawax creates thicker emulsions.

3. Some Emulsifying Wax Can Create Unstable Formulation.

There are some emulsifying waxes like BTMS 50 and BTMS 25, they are cationic emulsifiers, and substituting them with an anionic emulsifier can make the emulsion unstable. Also, Ritamulse SCG is an anionic emulsifier, and adding any cationic emulsifier can create an unstable emulsion. Ritamulse SCG is pH sensitive and has an oil phase size limit. Glyceryl Stearate SE emulsifier requires some gum or gelling agent to make a stable emulsion.

4. The Effectiveness Of The Emulsifying Waxes

Emulsifying waxes like BTMS 50 and BTMS 25 are cationic emulsifiers. They are generally used for making hair care products because BTMS emulsifier is great in conditioning hair and gives extra-slip to use the product. Substituting it with another emulsifier like emulsifying wax nf or Polawax, the formulation will lose its effectiveness and will not work as the original formulation.

Ritamulse SCG has a high soaping effect. This effect finds use in shampoos and conditioners. On the other hand, Olivem 1000 improvises the liquid crystals on the skin, essential for removing wrinkles and marks.

No Comments